To produce these areas, laser chopping provider vendors employ amongst 3 different types of laser chopping: fusion chopping, oxidation cutting or scribing. Each individual procedure usually provides considerably less contamination, Actual physical damage and waste, which contributes to material Value financial savings for the maker.

This blog publish is meant to help you obtain a far better understanding of the laser cutting procedure so you are very well educated in deciding upon the right laser cutting services vendor.

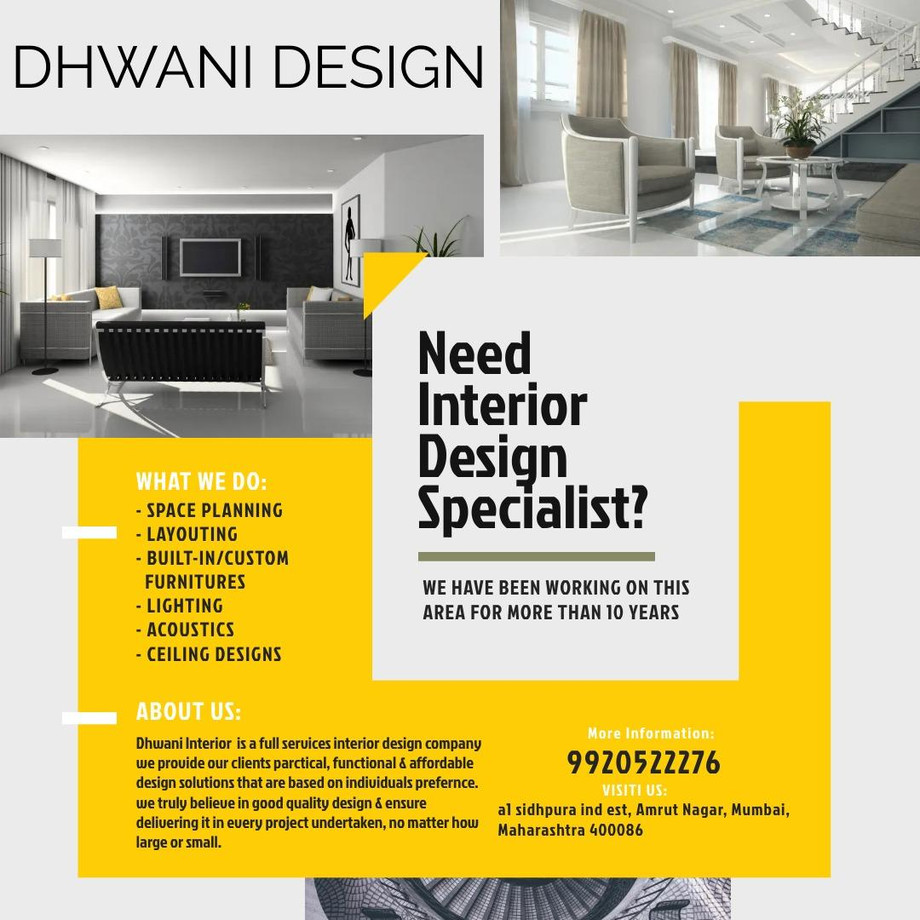

best Laser Cutting Service Provider in Mumbai Dhwani Design

The Laser Cutting Procedure and Equipment

Laser chopping is usually a thermal-centered, non-contact fabrication system suited to slicing steel and non-metallic products. Unlike mechanical chopping, which utilizes electricity-driven chopping equipment, laser chopping makes use of a laser chopping device to make cuts, markings and engravings.

The Laser Reducing Procedure

Fundamental laser cutting consists of the the subsequent levels:

Beam era: The laser beam is generated by way of spontaneous or stimulated emission.

Beam concentrating: The beam enters with the nozzle that directs the world of influence.

Localized heating and melting: The beam is absorbed by the material that raises in inside Power and heat era.

Substance ejection: As part of the heating and melting approach, parts of the fabric are vaporized to provide the desired Minimize.

Beam movement: Movement and reducing are realized through reflective mirrors, laser head motion or workpiece manipulation.

Every stage is essential on the laser reducing approach and manufacturing a exact Lower. Depending upon the material and type of Slash, laser reducing also employs inert or active guide gasses.

Kinds of Laser Cutting Devices

Whilst laser cutting devices differ in subtle approaches from 1 product to the next, a laser chopping machine is often arrange to incorporate a laser resonator assembly, mirrors plus a laser reducing head, which is made of a laser concentrating lens, a nozzle and a pressurized gasoline assembly.

The differing types of laser reducing equipment are categorized into fuel, liquid and sound-state lasers. The main two different types of lasers employed by laser devices are CO2 and stable-condition lasers:

CO2 lasers: These are typically utilized to Slice non-metal components. Despite the fact that laser technologies has advanced to allow CO2 lasers to chop metallic, they remain far better suited for chopping via supplies for example rubber, leather-based or wood.

Sound-point out lasers: These are typically produced from crystal or fiber that let for prime-powered metallic cutting. Crystal lasers are extremely multipurpose in conditions of fabric cutting abilities. Having said that, they are usually costlier and have shorter lifespans. Alternatively, fiber lasers are less costly and for a longer time Long lasting.

When exploring a laser cutting provider vendor, make certain to determine what sort of laser equipment they've got in their machinery established. As you'll be able to see, There are a selection of various equipment that happen to be a lot more suitable for specific duties, rather than all brands have each piece of equipment accessible.

The key benefits of Laser Chopping

Laser slicing gives quite a few rewards—together with versatility, repeatability, Price-success and pace—within the generation strategy of exact, superior-high quality and functional factors. By using best techniques, your laser slicing services vendor should give the next options:

a. Chopping Precision and Accuracy

Unlike most regular slicing devices, laser cutting devices create an array of cuts and styles that offer a lot more precision and accuracy. Laser cutting equipment are frequently absolutely CNC managed, which suggests that they have got high repeatability in producing complete, intricate components. The higher-excellent cuts produced by lasers commonly don't want further cleansing, dealing with or ending, which decreases the need for secondary processes.

b. Fewer Materials Contamination and Squander

Due to the fact lasers utilize a concentrated beam which allows for narrower kerf widths, the level of product removed is minimized. With minimal thermal input from localized heating, the warmth-influenced zones are minimized, which also decreases the thermal distortion. If thermal temperatures are way too higher, the material may be harmed, rendering the part useless.

c. Lessen Maintenance and Repair Costs

In comparison with other chopping equipment, routine maintenance prices for laser reducing equipment are comparatively low. In addition, laser cutting machines never involve shifting out individual tools to complete various operations, which decreases both of those the tools costs and direct time in between procedures. At last, laser factors experience considerably less exhaustion because laser chopping is really a non-contact process.

d. Bigger Operator Security

Laser reducing includes a reduced danger of operator injury since it employs very little to no mechanical components. With a peaceful operation, laser chopping is considerably less distracting than louder procedures. With considerably less conversation With all the device and fewer sounds, the general office environment is safer.

Choose the Perfectly-Geared up Laser Chopping Service Vendor

By picking out Dhwani Design as your laser reducing support seller, you will have a crew Together with the capabilities and equipment to work with many different resources, satisfy complex specifications and supply the correct prototype continuously, by the due date and inside finances.